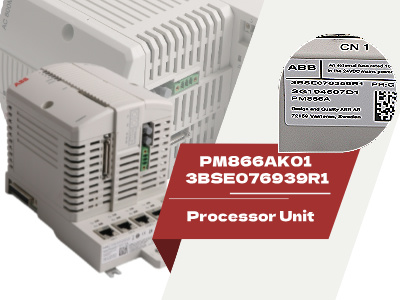

Introduction to the ABB PM866AK01 Processor Unit The ABB PM866AK01 Processor Unit (also known by the article number 3BSE076939R1) is a powerful and versatile CPU designed for industrial automation systems. Ideal for control applications, this processor unit ensures high-speed performance, reliability, and robust connectivity for modern control systems. Let’s dive deeper into its specifications, features, and benefits that make it an essential component in automation networks. Key Specifications of the ABB PM866AK01 Processor Unit The PM866AK01 Processor Unit is built to meet the demanding requirements of industrial environments. It features a clock frequency of 133 MHz, ensuring fast data processing and real-time control capabilities. The unit supports 64 MB of memory, with 51.389 MB of RAM available for application, allowing for efficient operation in complex systems. Performance Metrics: Clock Frequency: 133 MHz Performance: Handles 1000 boolean operations in 0.09 ms RAM for Application: 51.389 MB This performance level enables the processor to handle real-time data efficiently, ensuring smooth system operation even in high-demand applications. Connectivity and Expansion Options One of the standout features of the PM866AK01 Processor Unit is its extensive communication and connectivity capabilities. The processor includes two RJ45 Ethernet ports for seamless integration into the Control Network. Additionally, it provides two RJ45 serial ports, offering both RS-232C modem control and isolated connections for configuration tools. Communication Ports: Ethernet Ports: 2 x RJ45 (CN1, CN2) Serial Ports: 2 x RJ45 (COM3, COM4) with RS-232C and isolated port for configuration tools These communication options ensure flexibility and high compatibility with other components in industrial automation systems. Key Features and Benefits of the ABB PM866AK01 Processor Unit The PM866AK01 is designed with a number of key features that enhance its reliability and performance. These include: ISA Secure Certification: Ensures secure communication and data integrity. Modularity: The processor unit can be expanded step-by-step, allowing for future growth of your control system. Reliability: Simple fault diagnosis procedures make troubleshooting efficient. IP20 Class Protection: Offers protection against dust and other contaminants without requiring additional enclosures. EMC Certification: Fully certified for electromagnetic compatibility to ensure smooth operation in various industrial environments. Redundant Ethernet Communication Ports: This processor unit also includes redundant Ethernet communication ports, ensuring continuous and secure communication for critical applications where downtime is not an option. Simplified Installation and Fault Diagnosis The PM866AK01 Processor Unit is designed for ease of installation and maintenance. With its unique slide & lock mechanism, the unit can be easily mounted and detached from DIN rails. Additionally, the unit inc...

Read More

IPv6 network supported

IPv6 network supported