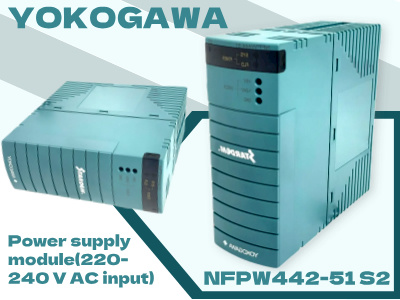

Understanding the Basics of Power Supply Modules Power supply modules are crucial components in various electronic systems, converting and regulating voltage for optimal performance. The Yokogawa NFPW442-51 S2 stands out due to its robust design and impressive specifications. Key Specifications of the NFPW442-51 S2 This module operates with a rated input voltage of 220 to 240 V AC, featuring a broad input voltage range of 170 to 264 V AC. It can handle input frequencies between 47 to 66 Hz, making it versatile for different applications. Performance and Protection Features The NFPW442-51 S2 delivers a rated output voltage of +5.1 V DC and supports output currents up to 7.8 A. With built-in overvoltage protection and overcurrent safeguards, it ensures reliability even under stressful conditions. Application Areas Due to its specifications, this power supply module is ideal for industrial automation, data acquisition systems, and other demanding environments where stability is paramount. Advantages of Choosing the NFPW442-51 S2 With features like a high withstand voltage of 3000 V AC and a short startup time, the NFPW442-51 S2 is designed for efficiency and durability, making it a top choice for engineers and developers alike. Conclusion The Yokogawa NFPW442-51 S2 Power Supply Module exemplifies advanced engineering with its comprehensive protection features and reliable performance, solidifying its position as a key model in the market. For those seeking a dependable power solution, it remains an ultimate choice. Email: plcinfo@mooreplc.com | WhatsApp: +86-18020776786 | Skype: plcinfo@mooreplc.com Yokogawa NFBU200-S16 S1 Yokogawa ANT512-10 S1 Yokogawa NFBU200-S01 S1 Yokogawa ANT411-50 S1 Yokogawa NFAI135-S51 S2 Yokogawa ANT502-10 S1 Yokogawa NFDV551-P11 S2 Yokogawa ANT502-50 S1 Yokogawa NFAI835-S51 S2 Yokogawa PW482-10 S2 Yokogawa NFAI143-S01 S1 Yokogawa PW481-10 S2 Yokogawa NFPW442-11 S2 Yokogawa CP461-10 S1 Yokogawa NFPW442-51 S2 Yokogawa CP451-10 S2 Yokogawa NFDV161-P51 S2 Yokogawa SPW482-13 S1 Yokogawa NFDV561-P51 S2 Yokogawa SPW481-13 S1 Yokogawa NFDV161-P01 S2 Yokogawa SSB401-13 S1 Yokogawa NFSB100-S01 S1 Yokogawa SNT401-E3 S1 Yokogawa NFCP501-W05 S2 Yokogawa SNT401-13 S1 Yokogawa NFCP501-S05 S1 Yokogawa SNT401-53 S1 Yokogawa NFTA4S-00 S2 Yokogawa SNT501-13 S1 Yokogawa NFSBT02 S1 Yokogawa SNT511-5F S2 Yokogawa S9562FA Yokogawa SNT501-E3 S1 Yokogawa S9342FA Yokogawa SNT411-5F S2 Yokogawa ANT421-50 S1 Yokogawa SNT521-53 S1 Yokogawa ANT411-5F S1 Yokogawa SDV144-S53 S4 Yokogawa SB401-10 S1 Yokogawa ANB10D-410 S2 Yokogawa ANT401-50 S1 Yokogawa SNB10D-213 S2 Yokogawa ANT512-5F S1 Yokogawa AFV10D-S41101 S2

Read More

IPv6 network supported

IPv6 network supported