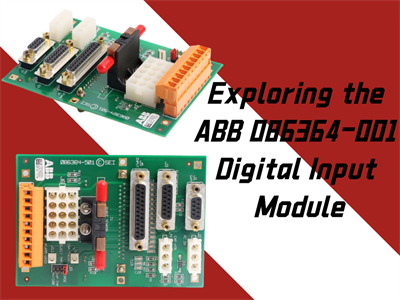

Overview of the ABB 086364-001 The ABB 086364-001 Digital Input Module is a reliable and efficient component designed for modern automation systems. Known for its high performance, this module plays a crucial role in managing digital signals in various industrial applications. Key Specifications One of the standout features of the ABB 086364-001 is its compact design, measuring 12.6 cm in length, 8.9 cm in width, and 4.6 cm in height. This small footprint makes it easy to integrate into existing systems without requiring extensive modifications. Additionally, the module weighs only 0.14 kg, allowing for straightforward installation and maintenance. Origin and Quality Assurance Manufactured in Sweden, the ABB 086364-001 module adheres to stringent quality standards. ABB is renowned for its commitment to excellence, ensuring that each product is built to withstand the demands of industrial environments while maintaining high levels of reliability. Applications in Industry The ABB 086364-001 Digital Input Module is suitable for a wide range of applications, including manufacturing automation, process control, and machinery monitoring. Its ability to process digital signals efficiently makes it an invaluable asset for industries looking to enhance their operational capabilities. Installation and Maintenance Tips When installing the ABB 086364-001, it's essential to follow the manufacturer's guidelines for optimal performance. Regular maintenance checks can help ensure longevity and reliability. Keeping the module free from dust and ensuring proper connections can significantly enhance its operational lifespan. Conclusion The ABB 086364-001 Digital Input Module stands out as a vital component for any automation system. With its compact design, lightweight construction, and robust manufacturing standards, it offers exceptional performance in various industrial applications. Embracing such technology can lead to improved efficiency and productivity in your operations.

Read More

IPv6 network supported

IPv6 network supported